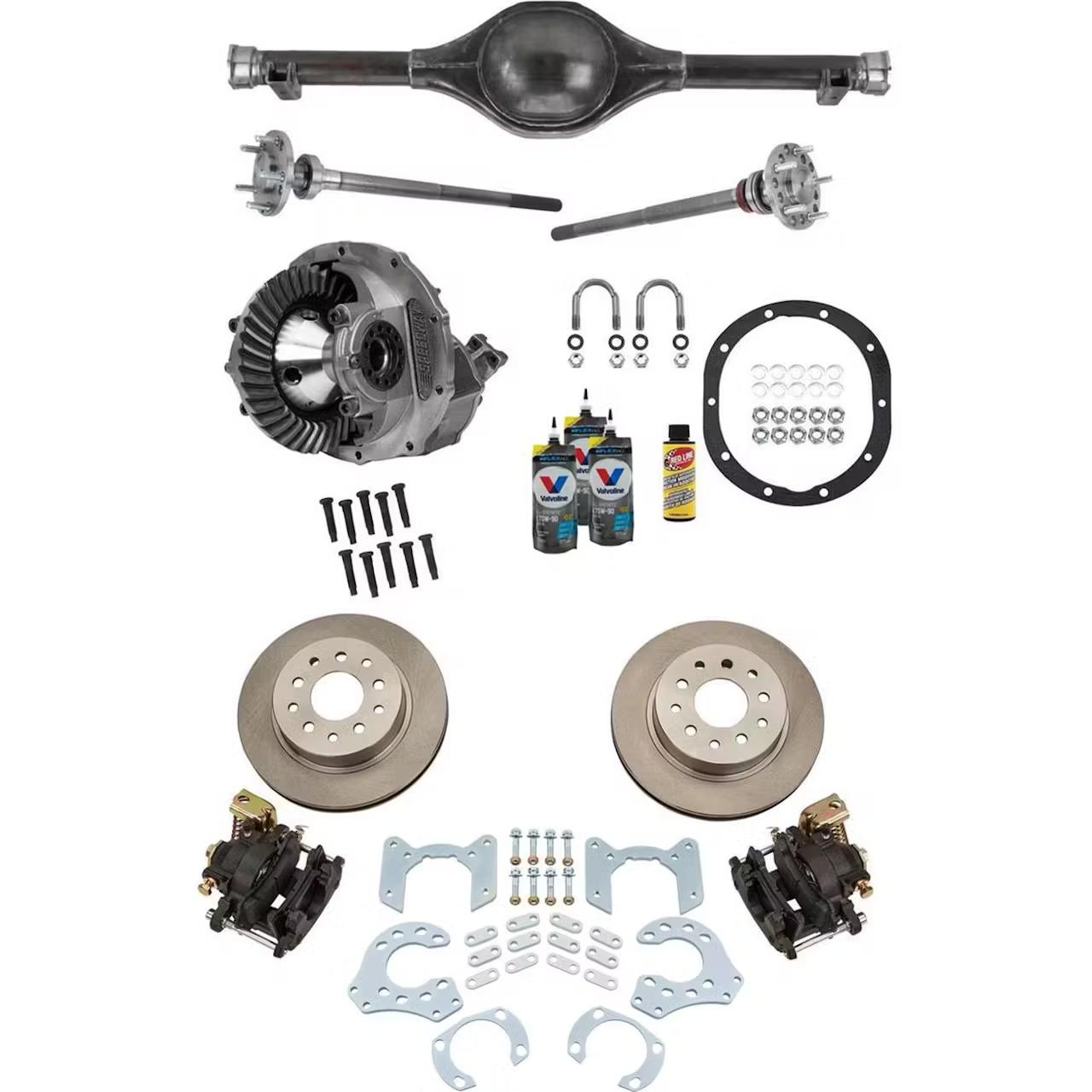

9 Inch Ford Rear Axle Kit w/Posi 3rd Member, 56 Inch.

$1,780.00

Installation Tips !

Additional Information:

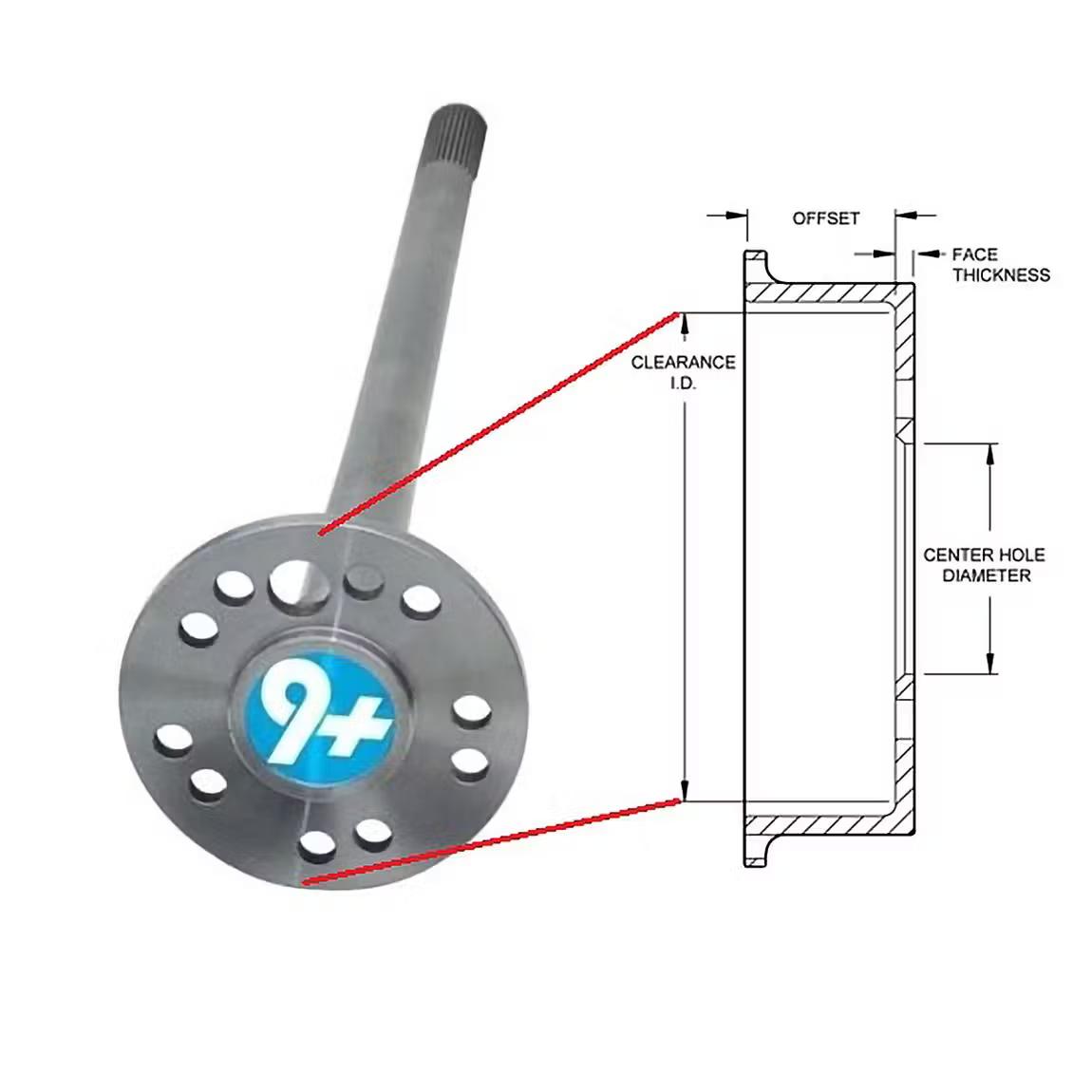

When utilizing an aftermarket axle with disc brake conversion kits, it may be necessary to reduce the diameter of the axle flange to a diameter necessary to adequately fit inside the required Clearance I.D. that the brake hat/brake rotor will require. (see above diagram for illustration)

Racing applications with 10.5” tires, drag radials or slicks are better suited for the more expensive locker and Powertrax style carrier designs.

All third members are assembled by our team of professionals and are delivered to you in a handy plastic carrying case, for an overall value that can’t be beat.

Available in your choice of 3.00, 3.25, 3.50, 3.70, 3.89, 4.11 or 4.56 gear ratio in 31 spline.

Total wheel-to-wheel mounting surface width is 56″ (from hub-to-hub). The pumpkin is centered in the housing, which puts the pinion 1″ offset from center, requiring different length axle shafts. This 56″ housing kit includes one 28-5/8″ long axle and one 26-3/8″ long axle. These custom cut and splined axle shafts are manufactured from an induction heat treated 1541 forged alloy. These axles are specific to the aftermarket brake configuration standard in that they have a 2.5″ brake space offset, 2.8″ register hub and include late model large bearings (Torino bearings). Flanges are dual-drilled for both 5 on 4-1/2″ Ford/Mopar and 5 on 4-3/4″ GM wheel bolt patterns.

Because there are no friction plates, no friction modifier additive is necessary. Always use a 80W-90 weight petroleum based gear oil with a GL-5 (or higher) rating, friction additive/modifiers should NOT BE USED. Synthetic oils and oils containing friction modifiers are not recommended.

Details

Save the time and headache of choosing the right parts for your Ford 9 inch rear end assembly and let the experts choose a quality, hand-assembled, street-tough complete package for you at the right price.

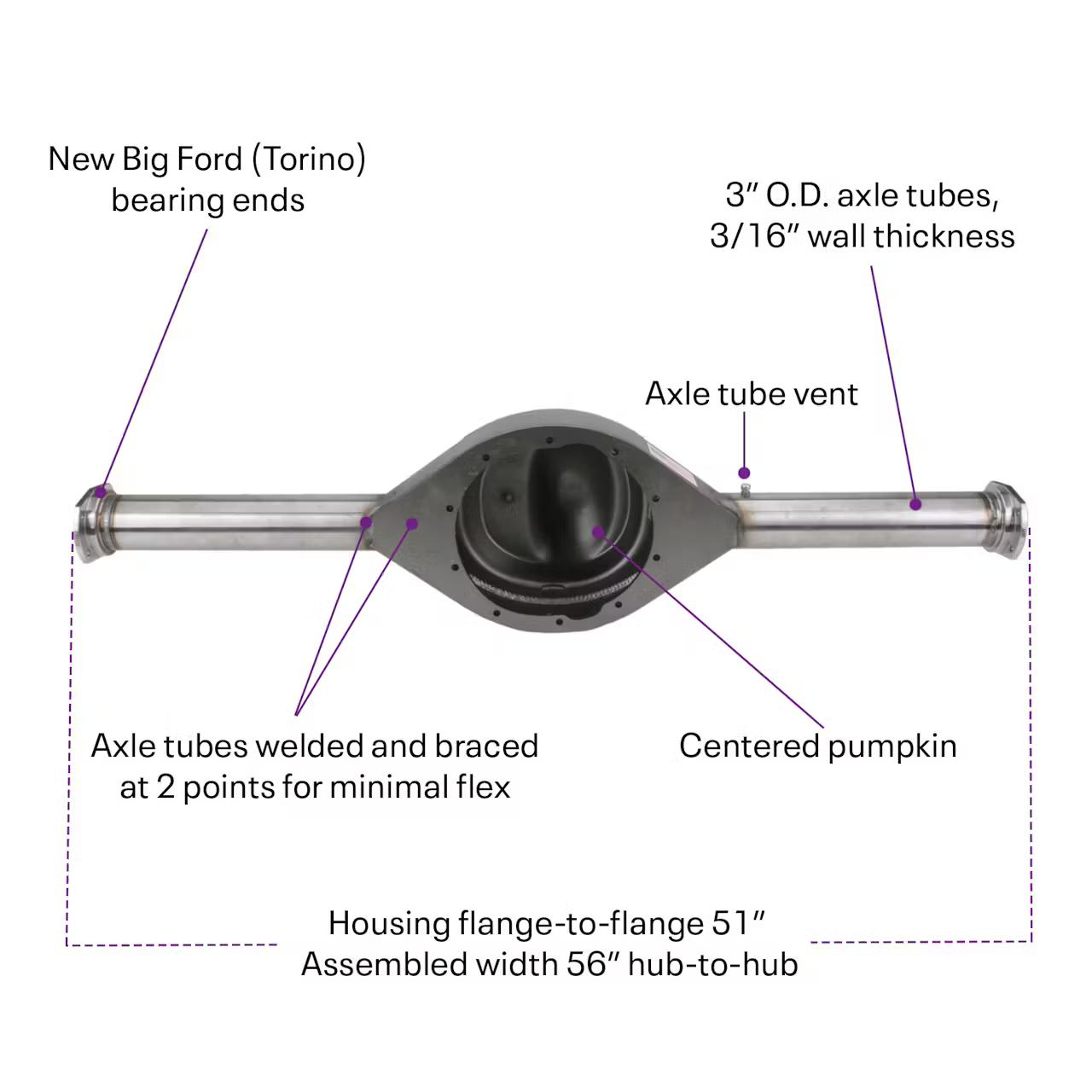

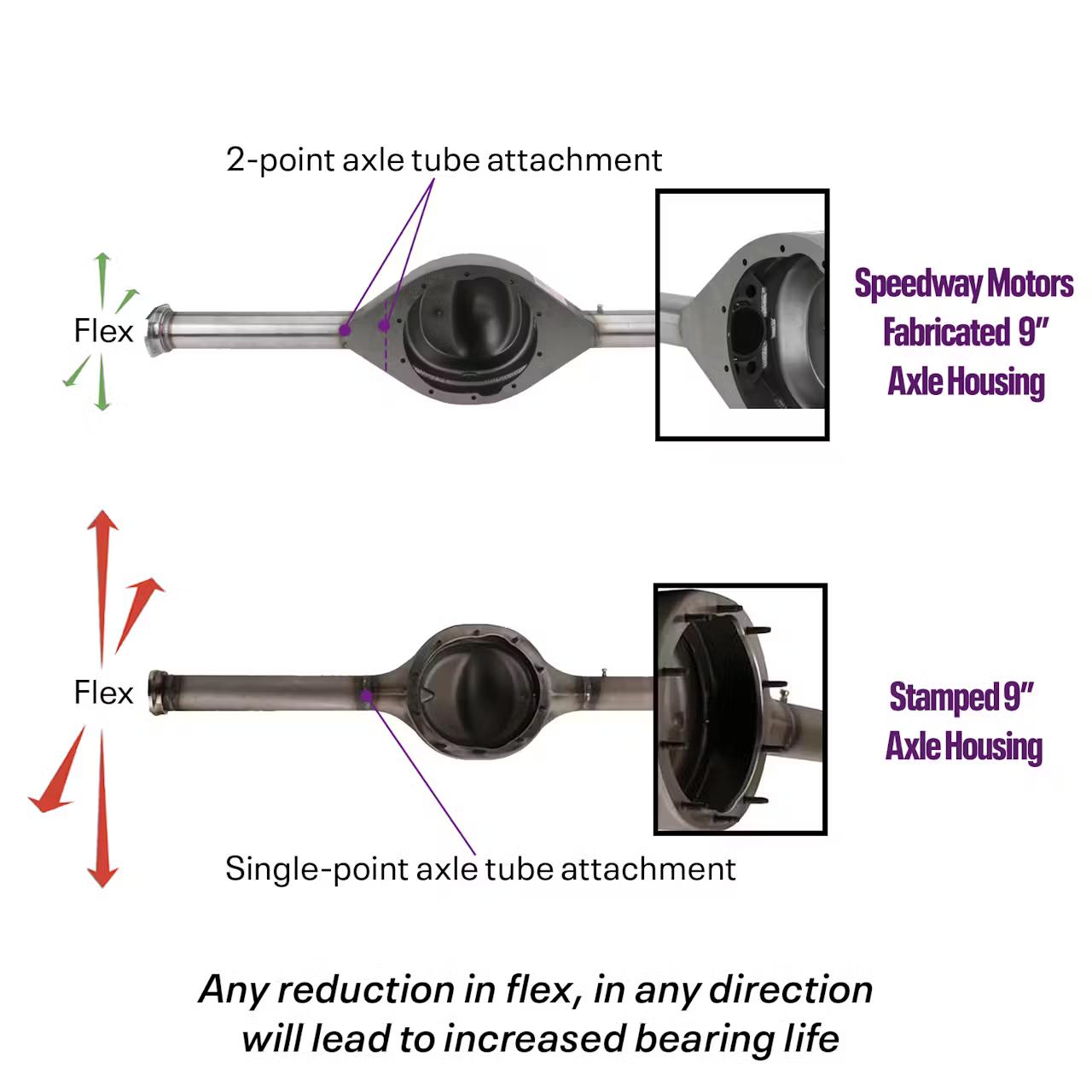

Stronger, Fabricated Steel Axle Housing with Forged Axles

Designed for your restoration, upgrade or custom build we start with our NEW fabricated steel axle housing. Our housing design is pumpkin-centered and improved with two points of support on the axle tubes to reduce tube flex, instead of support only on the single weld point of traditional stamped steel housings. A greater-than-stock capacity center section holds more gear oil and runs cooler. This housing includes (8) T-bolts for the axle bearing retainer plates and (10) studs for the third member. And yet, while improving strength, we have made our axle housings on average, 2 pounds lighter than stock style housings.

Fitted with “New Big Ford” (Torino)-style bearings and a 3” O.D. axle tubes, this housing also includes forged steel axles, bearings, seals and retainers. Flanges are dual-drilled for both 5 on 4-1/2″ Ford/Mopar and 5 on 4-3/4″ GM wheel bolt patterns and includes two sizes of wheel studs (1/2″-20 Ford/Mopar and 7/16″-20 GM).

We finish off the axle assembly with Forged 1541 Steel Currie Enterprises axles.

- 3″ O.D. axle tubes with 3/16″ wall thickness

- Billet steel “New Big Ford” (Torino) style bearing ends

- Forged Currie Enterprises 1541 Steel axles, dual drilled for both 5 on 4-1/2″ Ford/Mopar and 5 on 4-3/4″ GM wheel bolt patterns.

- Accepts brake kits for 2.50″ axle shaft flange offset (from housing flange)

- Housing measures 51″ from flange-to-flange

- Assembled rearend measures 56″ from hub-to-hub (axle flange face-to-face)

- Includes one 28-5/8″ long axle and one 26-3/8″ long axle in your choice of 28 or 31 spline

- Centered pumpkin w/ 1″ offset pinion yoke for easy suspension mock-up

- Greater-than-stock capacity center section holds more gear oil and runs cooler

- Includes vent on driver side axle tube

- Includes studs for 3rd member and 3/8” T-bolts for bearing retainer plates

Precision Built Third Member with Nodular Iron Carrier Housing

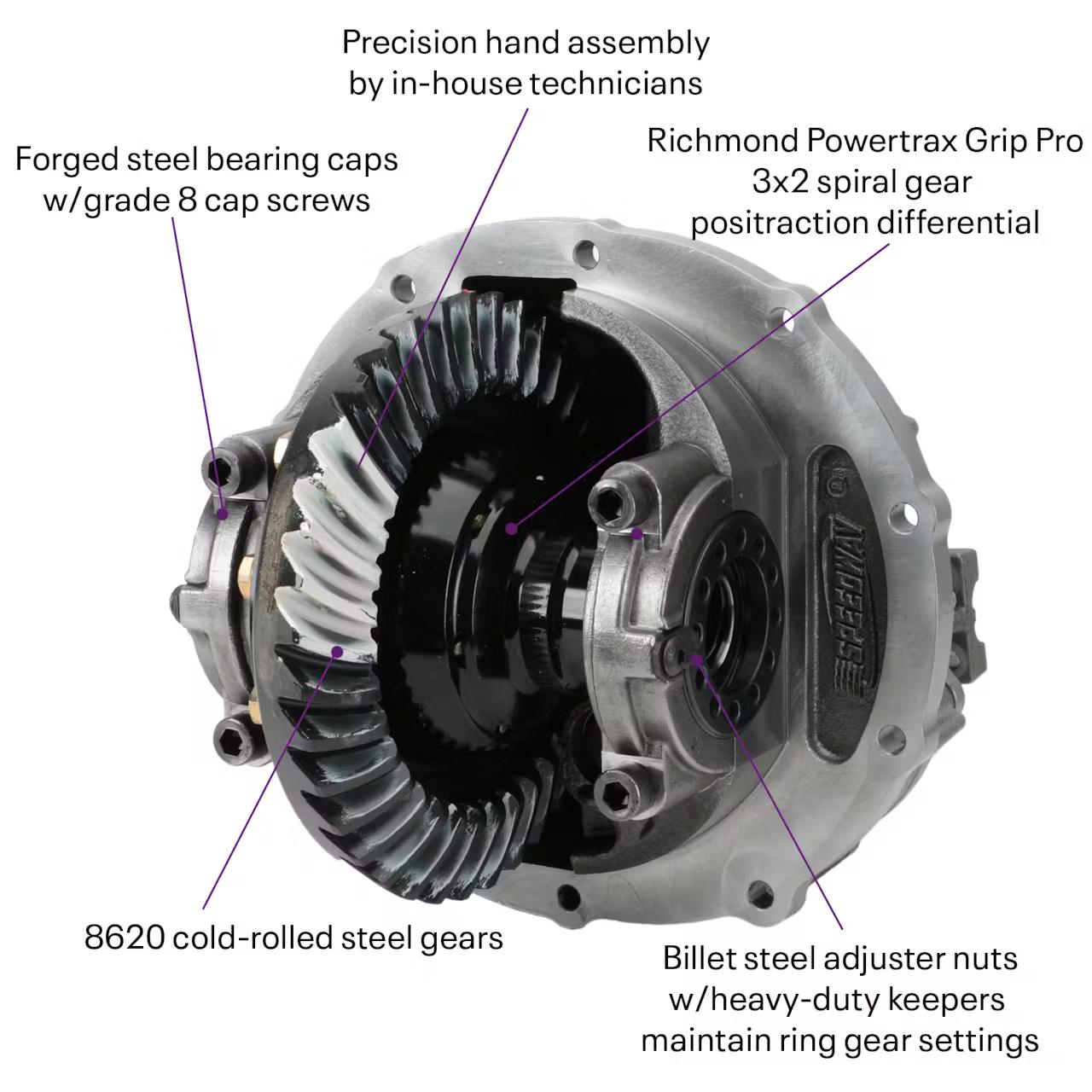

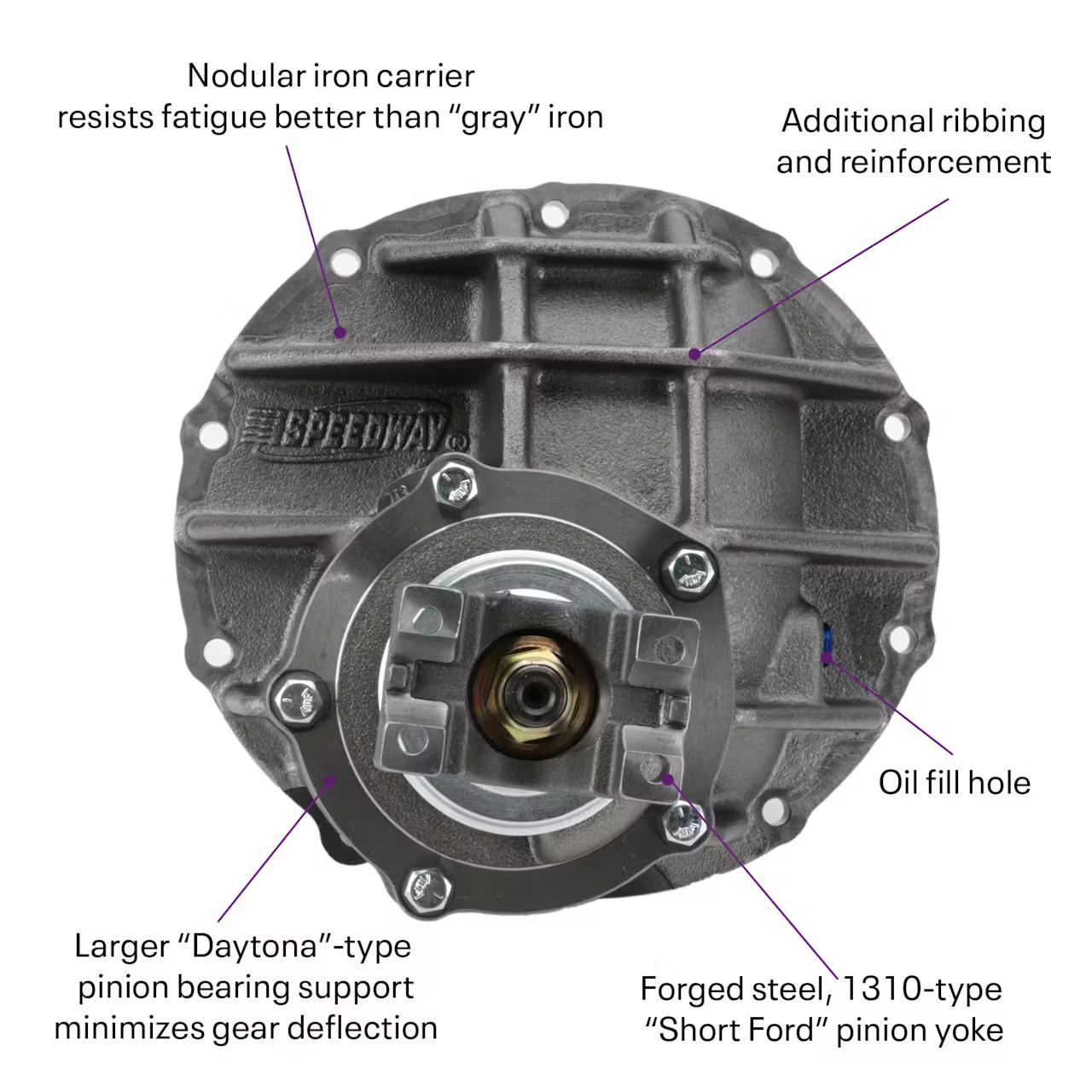

Our third member assemblies are precision assembled, in house by our trained technicians with new, quality components. You choose the gear ratio and we take care of the rest. We start with a new carrier housing, re-designed and constructed of reinforced nodular (ductile) iron that is far stronger than OEM ‘gray’ cast iron housings. Nodular iron resists fracturing far better than traditional gray iron and is the metal of choice for the demands of high horsepower and torque. Machined surfaces and a Viton® pinion seal keep the leaks off your shop floor.

We have reinforced the rearmost pinion (pilot bearing) support and use a large “Daytona” nodular iron pinion bearing support with a spacer and shim assembly to maintain perfect pinion gear alignment and long life. The spacer/shim stack gives durability and ease of service. The larger oiling channels of the Daytona bearing support also add to long bearing life. We included a NEW, forged steel 1310-style “Short Ford” pinion yoke to round off this durable assembly.

Ring and pinion gears are built of long-wearing 8620 cold-rolled steel and assembled with Grade 9 hardware with Grade 8 carrier cap bolts. Billet steel adjuster nuts and heavy-duty keepers ensure your ring gear settings are maintained.

- Precision assembly for the correct backlash, preload, and proper amount of pinion shims to ensure the correct pattern on the ring gear teeth

- Nodular iron housing is stronger than OEM “gray” iron and has 4 lbs of additional reinforcement

- Large bearing “Daytona” style pinion bearing supports for strength and reliability

- New forged steel 1310-style “Short Ford” pinion yoke

- U-Joint Cap Size: 1-1/16, Yoke Width: 3-7/32″

- Spacer and shim setup maintains critical pinion depth settings and easier to service than traditional crush sleeves

- Gear units built of long-wearing 8620 cold-rolled steel, available in your choice of gear ratio

- Ring gears assembled with Grade 9 hardware, 15% stronger in tensile strength than Grade 8

- Viton® pinion seal, resistant to chemicals and high temperatures

- Grade 8 Carrier cap bolts

- Lock-style pinion nut with pre-applied Loctite®

- Grade 5 pinion support bolts

Ford 9 Inch Helical Gear Posi 3rd Member Assembly

Our helical style limited-slip differential works with any factory Ford 9 inch differential case, gear, axles and bearings. The helical-gear design gives quiet operation, with no clicking when disengaging for corners. While under normal conditions the helical-gear style performs like an open differential, when required the differential automatically transfers torque to the wheel with the highest traction. Smooth power transfer is unnoticed by the driver.

When you want the traction benefits of a limited slip differential in your Ford 9 inch rearend without the expense and noise of a full-locker unit, our helical style differentials are just the ticket.

Proven Reliability

We run what we sell. Our third member units are the go-to choice for our own rides and we have built these units to last with high quality hardware and components. Tapered steel roller bearings minimize friction, better handle thrust loads and increase load carrying capacity. The ring gears are assembled with Grade 9 bolts with a tensile strength of 180,000 psi, a 15% increase over Grade 8 hardware. Heavy duty Grade 8 carrier cap bolts, a lock-style pinion nut with pre-applied Loctite and high-quality grade 5 pinion support bolts make our third member near-bulletproof.

Units include a Viton® pinion seal providing long lasting oil and chemical resistance. This seal retains elasticity up to 399°F (204°C) and intermittently up to 600°F (316°C) This high temp seal helps eliminate pinion leaks, reduces maintenance and keeps the third member properly lubricated. A carrier-to-housing gasket is available separately.

Our hand-assembled Ford 9 inch third member assemblies are made-to-order. We keep a supply of the most popular gears in stock, with most units built within 2-3 days. Our third-member units are shipped in a durable, reusable poly storage case, perfect for keeping multiple gear sets stored and ready for the track.

Features

- Hand-assembled by our trained technicians for an unbeatable combination of quality and value

- Track-tested durability in our own cars – we race what we sell

- Precision assembly for the correct backlash, preload, and proper amount of pinion shims to ensure the correct pattern on the ring gear teeth

- Ring and pinion gears of 8620 cold-rolled steel for long wear

- Nodular iron housing is stronger than OEM “gray” iron and has 4 lbs of additional reinforcement

- Large bearing “Daytona” style pinion bearing supports for strength and reliability

- Spacer and shim setup maintains critical pinion depth settings and easier to service than traditional crush sleeves

- Helical gear differential gives positive traction without the noise of a full locker

- Ring gears assembled with Grade 9 hardware, 15% stronger in tensile strength than Grade 8

- Viton® pinion seal, resistant to chemicals and high temperatures

- Grade 8 Carrier cap bolts

- Lock-style pinion nut with pre-applied Loctite®

- Grade 5 pinion support bolts

- Includes form fitted, reusable red poly storage case

- Choose gear ratio – 3.25, 3.50, 3.70, 3.89, 4.11, or 4.56

Charts

-

Instructions (PDF)

Reviews

There are no reviews yet.