Building a Traditional Hot Rod Front End Requires Choosing the Right Transverse Leaf Spring

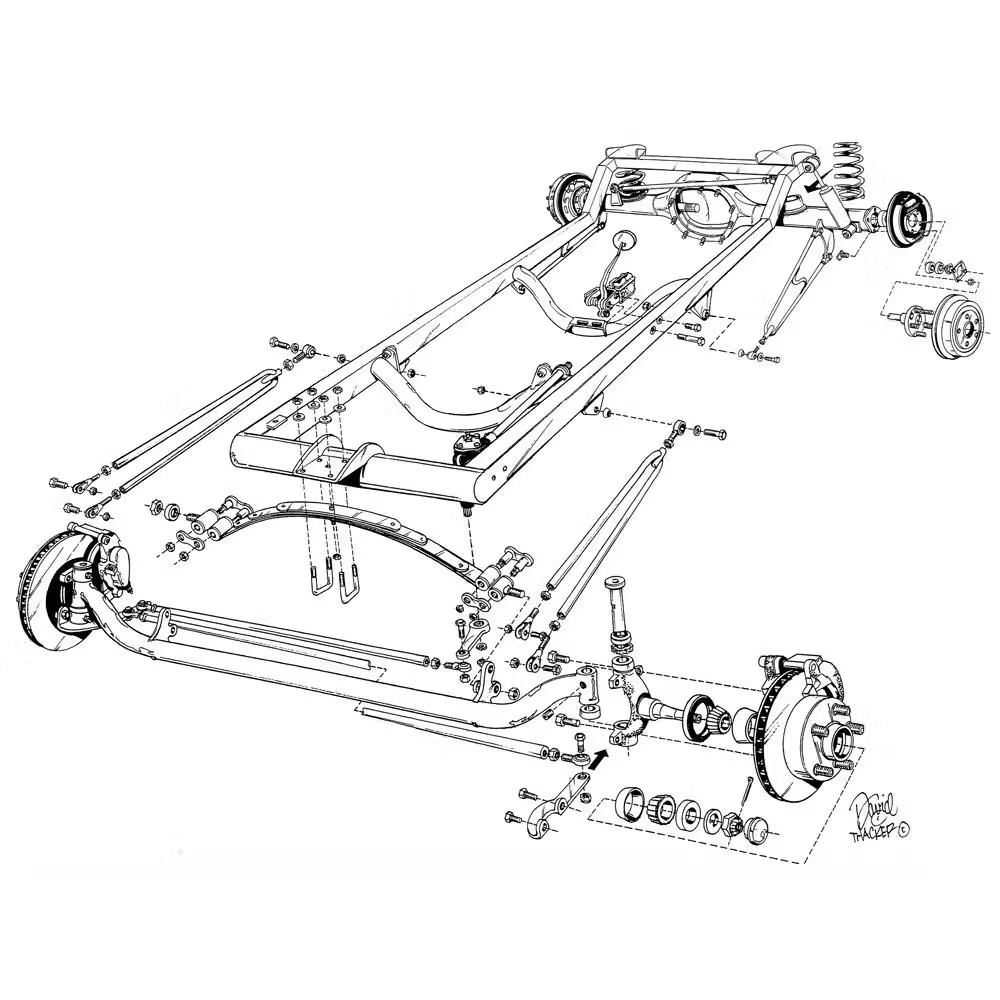

Ford used a straight axle front suspension design with a single transverse mounted leaf spring from just after the turn of the century until the late 1940s. This application range covers just about every popular pre-war Ford hot rod body style we all know and love. Model Ts, Model As, ’32 Fords, and so on. While there are dozens of aftermarket frame and suspension options and complete kit car build variants of these models today that use independent front suspension (IFS), if you are looking to build a traditional-style street rod on any of these models you’re going to be running a straight front axle with either standard or split wishbones (learn more about wishbones in this Speedway Motors Toolbox guide) and you are going to have to pick a leaf spring that will work with your axle of choice and your intended ride height.

The traditional straight axle suspension is a very old design, no doubt, and it does have its disadvantages, such as noticeable bump steer and lack of lateral location/support of the front axle. That said, there are plenty of reasons to still run a solid axle suspension with a transverse leaf spring. Of course, keeping a traditional hot rod look is at the top for most enthusiasts, as it is front and center and quite visible on the car and frankly just looks “right” for these models. However, that said there is a lot in the “plus” column of the ledger here. The transverse leaf spring not only has less unsprung weight than a traditional IFS setup, but overall, it has a very good ride quality for its design with fewer suspension pieces in a simpler configuration. Will a straight axle front end with a transverse leaf spring pack win a Goodguys autocross? Not likely, but for a traditional hot rod build they are a must and can be made to run quite nicely while being safe on today’s roads.

How Do I Measure for The Correct Spring?

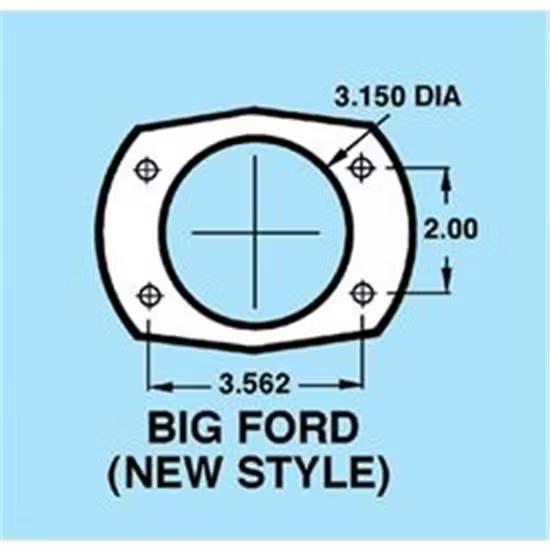

Spring length is determined by the axle width. So, if you do not have an axle in hand yet this can be a bit of a “cart before the horse” situation. As such, we recommend determining the correct straight axle kit for your street rod build with the amount of drop you want (if any). Our straight axle buyer’s guide will be a huge help in this regard to get you on your way to choosing the best axle for your project when shopping for your street rod parts. Once you have your solid axle of choice then you can determine what is the optimum spring length. Most axles will state on their product page or in their instructions what length spring to use, but for that barn find or swap meet straight axles you will need to confirm your spring mount center-to-center distance by measuring from the vertical spring perch mounting holes (center-to-center) on the axle and subtracting 5 inches.

For example, if your vertical spring perch mounting holes on your axle are 34 inches apart, you will need a leaf spring with 29 inches of free length, measured from the center of the spring’s eyes. This free length is measured from center-to-center of the leaf spring’s eyes, and not from the very end of the spring assembly. Conversely, if you have your spring perches and shackles already for your axle you can install them, level the shackles horizontally, and measure from the centerline of one shackle pin to the other. This will give you the direct spring length measurement you need, as the perches and shackles take up the 5-inch measurement deduction we previously mentioned.

While discussing spring measurement we cannot forget to discuss leaf spring free arch. The free arch of a leaf spring is defined as the measurement from the center of the spring eyes to the bottom surface of the leaf spring pack. The easiest way to take this measurement is to place the spring standing upright on the floor. Measure from the underside of the spring pack to the floor. Then measure from the spring eye’s center point to the floor. Subtract this second measurement from your first and it will give you the spring’s free arch.

What Is the Best Spring Material, Steel or Composite?

Both steel and composite leaf springs have been used in front and rear suspension systems for decades. From basic sedans to sports cars, steel and composite leaf springs have been a part of typical leaf spring suspension design. For our discussion on transverse straight axle leaf springs the majority of what is available today are steel leaf springs. While Speedway Motors does carry composite leaf springs, our current product line is mainly relevant to muscle car-era leaf spring rear suspensions. None the less, we do want to discuss both types of leaf springs here.

The typical steel leaf spring is made up a spring pack with anywhere from 3 or more individual leaves that are clamped and bolted together. Steel leaf springs are the most common style of leaf used in automotive suspension systems due to their load capacity and low cost. Their service life is quite long and in fact are still used today for things like car trailers. One of the main reasons new car manufacturers moved away from leaf springs was packaging. Automakers could provide smaller/tighter packaging using other suspension spring offerings versus the traditional leaf spring.

Composite leaf springs were designed to save weight and manufacturing costs, since composite leaf springs are usually a single leaf and not made up of a “spring pack” like a steel leaf spring. Though more expensive than a steel leaf spring, composite springs are known for having more consistent spring rates and extended service life. Today you will usually only find composite springs in performance rear suspension packages.

Reviews

There are no reviews yet.